Great Technologies

need great

materials

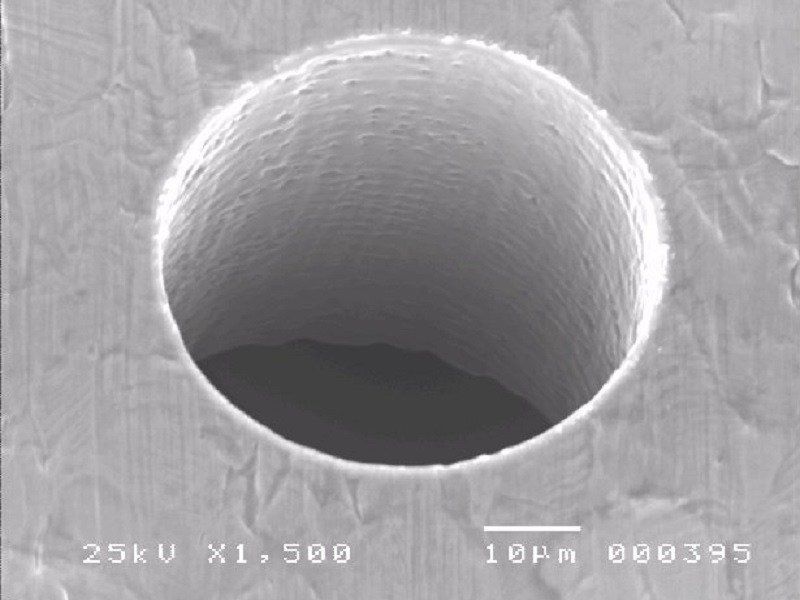

Micro bores in mechanical engineering - production of micro bores

Production of micro bores from a size of 10 microns.

The fields of application of microbores are wide, eg in the area of ventilation, filtering, injection.

Micro-holes of different diameters and depths can be made in almost any material.

Due to the use of ultra-short pulse lasers, almost no heat is introduced into the material and no melt pool is generated.

A sublimation of the solid takes place.

This opens up further areas of application in laser processing and etching technology can be replaced in some areas.

With this method, the micro-bore is produced with sharp outer contours and a reproducible quality is made possible.

Contact us for personal advice.

Micro Holes Machining

Laser micro drilling is used to create micro holes / micro holes in any material. We use self-developed pendulum technology to realize the smallest high-precision holes. Due to the piezo-controlled oscillation of the laser beam, exact contours can be achieved with high reproducibility.

Market trends are moving towards smaller and smaller holes with higher quality and process reliability. We have specialized in this and designed our processes.

We look forward to your orders in micro-machining and micro-drilling.

We use ultra-short pulse lasers to produce micro-holes. The advantage is that the material sublimes and does not go into the liquid phase. In this way, high-precision contours can be produced. The resulting dust is extracted during processing.