Great Technologies

need great

materials

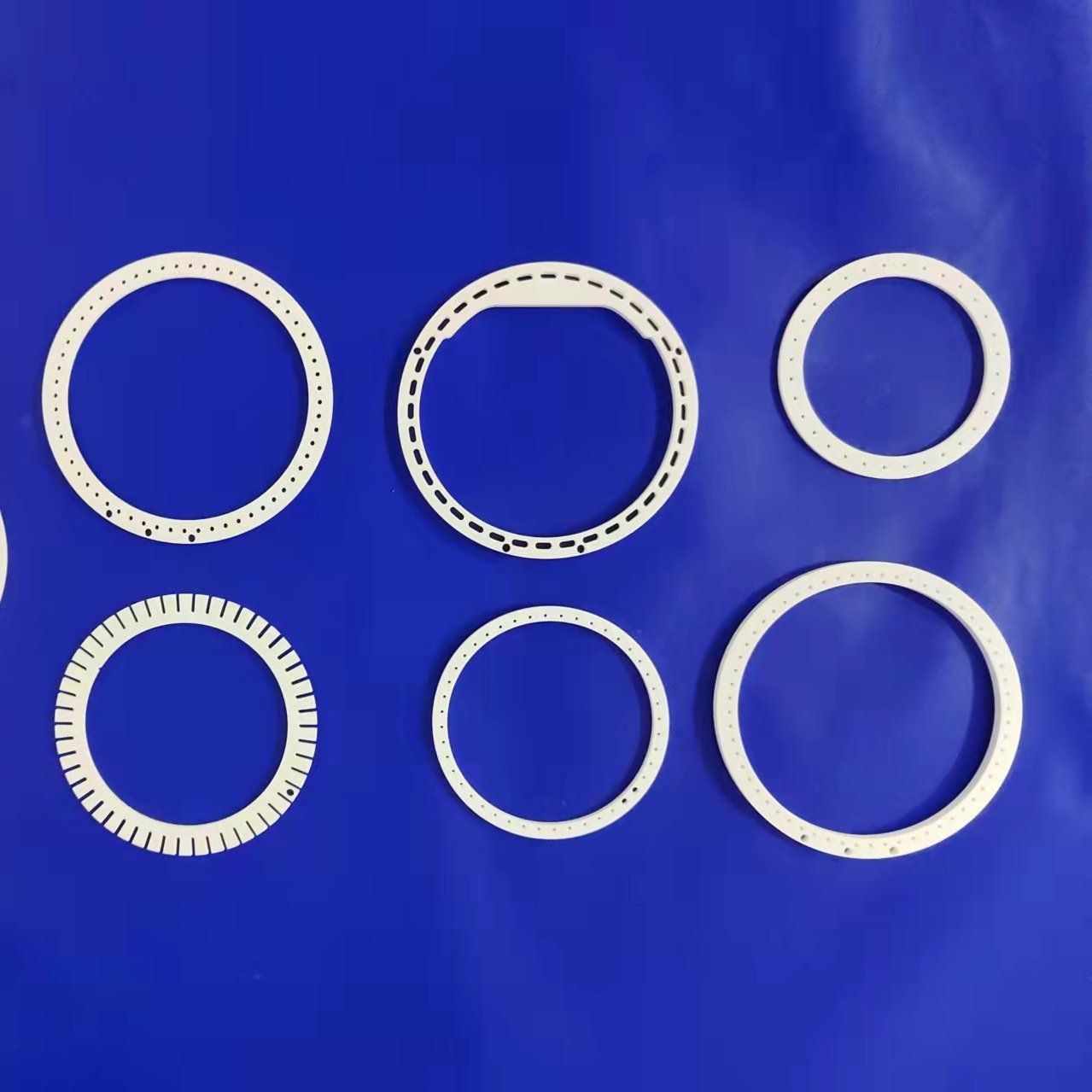

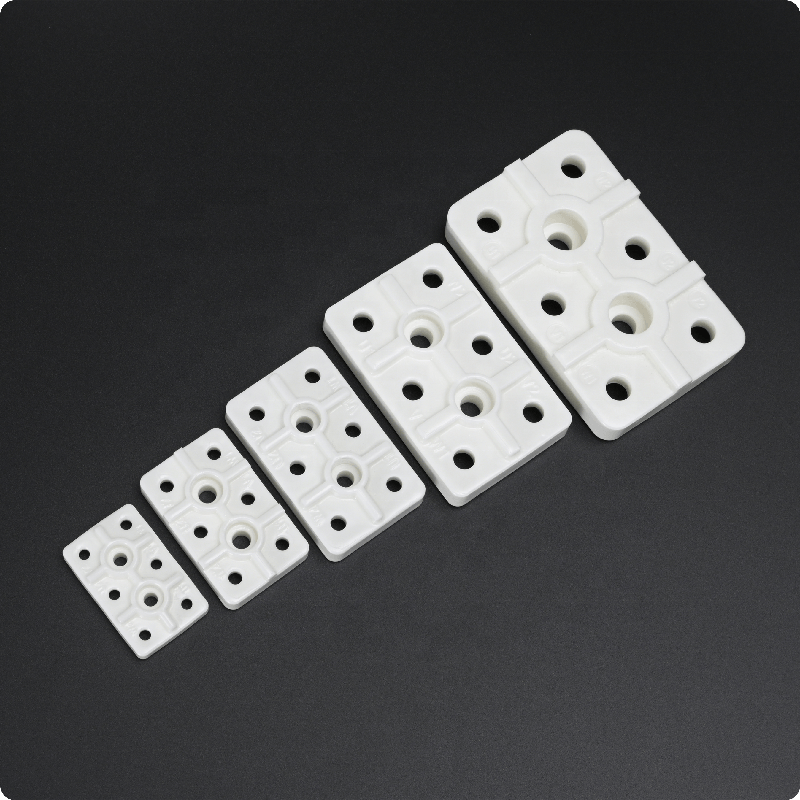

Laser cutting ceramics - aluminum oxide and aluminum nitride

Precision laser cutting of technical ceramics such as aluminum oxide or aluminum nitride

The advantages of laser processing lie in the flexibility to be able to produce any geometries quickly, precisely and cost-effectively. Due to our storage of different ceramic plates, we can quickly respond to your wishes.

Compared to the production of ceramic components using a sintering process, laser cutting does not require a press mold to produce the green part.

Laser cutting of ceramics is therefore also suitable for the production of prototypes and small series. With the right know-how, the economical production of large series can also be realized inexpensively by laser cutting. Especially when the ceramic components are too thin for a conventional sintering process, laser cutting of ceramics is a preferable process.

The following materials can be processed by laser cutting:

- Alumina (Al2O3) (96% or 99.6%)

- Aluminiumnitrid (AlN)

- Zirconium oxide (ZrO2)

- Siliziumcarbid (SiC)

- Silicon nitride (Si3N4)

- Glaskeramik / Glas

- Silicon (Si)

For laser cutting of other technical ceramics or glasses, please contact us directly.

For the laser cutting of technical ceramics such as aluminum oxide, we need a drawing as a PDF and a DXF file for complex geometries.

Section thicknesses of ceramics: 0.1mm - 6mm

Tolerance: /-0.03mm on bores and external dimensions

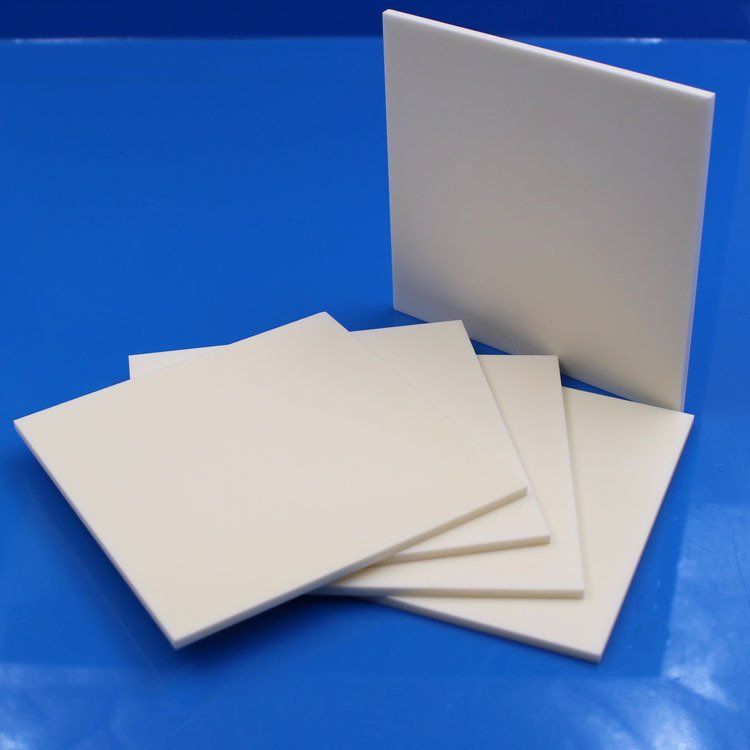

In addition to the laser cutting of Al2O3 ceramic components, we also supply ceramic substrates and plates as semi-finished products based on customer requirements.

Possible dimensions of aluminum oxide plates, aluminum nitride plates and technical ceramics:

0.1mm - 50mm -> Dimensions up to: 450mm x 450mm

More information about aluminum nitride and aluminum oxide ceramic plates can be found here.

Laser cutting alumina ceramics

Thanks to our many years of experience in laser cutting of aluminum oxide and technical ceramics, we can respond to the wishes of our customers individually and also implement complex projects in a timely manner.

We cut technical ceramics, especially with the laser, precisely, quickly and cost-effectively.

Depending on the geometry and requirements for the cut edges, we use CO2 lasers, but we also have the option of cutting the aluminum oxide with ultra-short pulse lasers. The advantage of processing with ultra-short pulse lasers lies in the "residue-free" material removal, which is particularly desirable when ceramics are to be coated afterwards or no material residues are to adhere to the substrates.

The disadvantage of laser cutting using USP lasers is the higher costs compared to conventional CO2 lasers.

Would you like to buy alumina ceramic sheets and do the ceramic laser cutting at your house? We are happy to offer you qualitative Al2O3 substrates for your internal processing. Learn more here.

We would be happy to advise you on the right choice of material for your project and the appropriate process for laser cutting the ceramic.

Examples Aluminum nitride and aluminum oxide ceramic components by laser cutting and sintering

Send us your request by email or use the contact form: