Great Technologies

need great

materials

Production of tungsten carbide semi-finished products and components according to drawings

Production of hard metal tungsten carbide semi-finished products and drawing parts according to customer requirements.

Have your carbide parts manufactured and processed by experts.

We sinter, grind and erode from a quantity of 1 to series production.

Carbide Tungsten Carbide - What is it?

Carbide is a sintered material and consists of two main components.

On the one hand made of tungsten carbide particles and on the other hand made of cobalt (or more rarely nickel).

The tungsten carbide is the hard phase in the hard metal and forms the hard metal structure with the cobalt as the binder phase.

Hardness, wear resistance and toughness are the main properties of cemented carbide. These properties are influenced by the grain size of the tungsten carbide and the proportion of cobalt. Thus, there are different types of hard metals that can be adapted to their application.

Carbide Tungsten Carbide - The Production

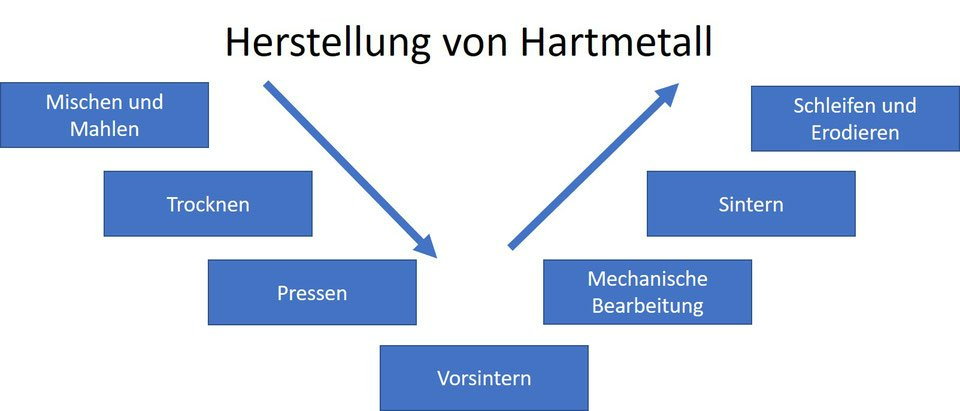

The production of cemented carbide takes place in 7 steps.

After mixing and grinding the hard metal particles with the cobalt, the powder is dried. The powder can then be pressed. Here we differentiate between linear and isostatic pressing. The result is a green compact that can be easily processed mechanically by turning and milling. Finally, the almost finished component is sintered and, after sintering, ground to size or eroded. Contact us, we will process your carbide according to your drawing.

Carbide: advantages and properties

Carbide has numerous advantages over other materials, making it an interesting and very important material for many applications.

hardness and wear resistance

The most well-known property of hard metal is its hardness. If you need a material with high wear resistance for an application, you often cannot avoid using carbide. The hardness of hard metals can be adjusted using the grain size of the tungsten carbide and the cobalt binder. Hardness increases with smaller grains and lower binder content. The hardness is usually given by Vickers hardness (HV) and ranges from 690 HV 30 to 2250 HV 30. Thus, the hard metal tungsten carbide is almost as hard as diamond or only diamond is harder than tungsten carbide hard metal.

toughness and breaking strength

The increase and decrease in toughness behaves according to the same rules for cemented carbide as for other materials. If you increase the hardness, you inevitably decrease the toughness. Since all types of hard metal have a high to very high level of hardness, the toughness is significantly lower than that of many other metals. The toughness can be compared to that of hardened steel. Carbide is therefore a brittle material, similar to ceramics there is no plastic deformation before fracture. In order to achieve the highest possible toughness and hardness values, ultra-fine tungsten carbide particles are used for production.

compressive strength

Compressive strength is not to be confused with ultimate strength because, as the name suggests, a different type of stress is applied to the material, namely compression (excluding tension and bending).

Carbide has an extremely high compressive strength when it is uniaxially loaded. With a decreasing grain size of the tungsten carbide and a lower binder content, the compressive strength increases so that a hard metal can achieve a compressive strength of almost 7000 N/mm².

density

Carbide has a higher density than many other metals due to the high density of tungsten carbide of 15.7 g/cm³. The density content varies slightly depending on the amount of binder.

corrosion resistance

Depending on the use of the carbide binder, the surface of carbide is more or less susceptible to corrosion.

If cobalt is used as a binder, this is reduced on the surface by corrosion and the properties of the hard metal are thus negatively influenced. However, if the cobalt binder is replaced with a nickel binder, the corrosion resistance can be significantly increased without affecting the excellent properties of the carbide.

Different carbide types - data sheet

Carbide Grades

Carbide data sheet of the different tungsten carbide grades

Data sheet tungsten carbide grades.pdf

Adobe Acrobat Document 81.3 KB

Download

Manufacture of tungsten carbide hard metal drawing rings, ironing rings, rings and drawing machined

Manufacture of tungsten carbide drawing rings / ironing rings and machining drawing.

We produce tungsten carbide components in different grades. We can therefore respond precisely to your special wishes and required properties of the material.

Depending on the change in the composition of tungsten and cobalt and the setting of the particle size, the properties of the hard metal such as hardness, flexural strength and thermal expansion coefficient change. Please refer to our for all the different tungsten carbide grades available

Machining hard metal tungsten carbide tools and dies

Buy tungsten carbide tools and matrices from experts in standard dimensions or have your carbide parts machined by us according to drawings. We sinter and grind your tungsten carbide parts from a quantity of 1.

You will find what you are looking for with us when it comes to the production of carbide components in different grades. This means that we can respond precisely to your special wishes and the required properties of the material.

Depending on the change in the composition of tungsten and cobalt and the adjustment of the particle size, properties such as hardness, flexural strength and the coefficient of thermal expansion change. All the different tungsten carbide grades available can be found in our data sheet, which you can download on this page.

Production of hard metal tungsten carbide rods, rods, stamps and tips including machining

Tungsten carbide rods, rods, punches and tips are sintered and ground according to customer requirements and can be manufactured and processed by experts.

We also process semi-finished products such as rods or rods according to customer requirements if the dimensions you require are not in stock.

We produce tungsten carbide components in different grades. We can therefore respond precisely to your special wishes and required properties of the material.

Depending on the change in the composition of tungsten and cobalt and the adjustment of the particle size, properties such as hardness, flexural strength and the coefficient of thermal expansion change. All the different tungsten carbide grades available can be found in our data sheet, which you can download on this page.

Manufacture of hard metal tungsten carbide cutting plates, saw teeth, scrapers, knives

Production of tungsten carbide cutting plates, saw teeth, knives and scrapers according to customer requirements, including machining with high dimensional accuracy.

We machine tungsten carbide components in different grades. We can therefore respond precisely to your special wishes and required properties of the material.

Depending on the change in the composition of tungsten and cobalt and the adjustment of the particle size, properties such as hardness, flexural strength and the coefficient of thermal expansion change. All the different tungsten carbide grades available can be found in our data sheet, which you can download on this page.

Production of hard metal tungsten carbide nozzles, nozzles for 3D printing or sandblasting systems - edit

Have your tungsten carbide nozzles, nozzles for 3D printing or sandblasting systems manufactured and processed by us according to your requirements. The carbide grade is manufactured and selected according to your specifications.

We produce tungsten carbide components in different grades. This means that we can respond precisely to your special wishes and the required properties of the material.

Depending on the change in the composition of tungsten and cobalt and the adjustment of the particle size, properties such as hardness, flexural strength and the coefficient of thermal expansion change. All the different tungsten carbide grades available can be found in our data sheet, which you can download on this page.

If you need semi-finished products or components made of pure tungsten or a tungsten alloy, you will be forwarded here.