Great Technologies

need great

materials

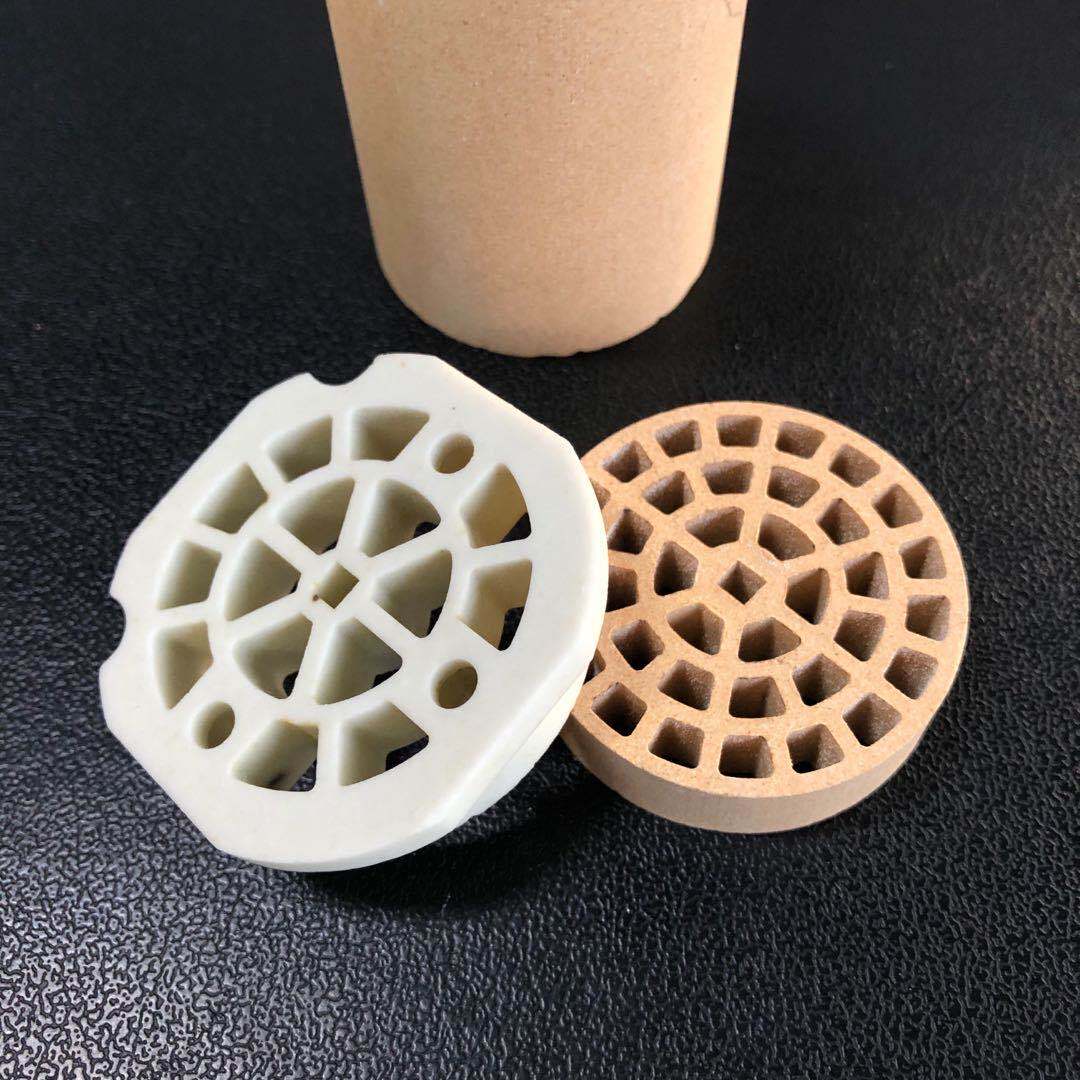

Cordierite ceramic C410 / C511/ C520 / C530 custom-made

Cordierite ceramic is a magnesium aluminum silicate mineral with a very low thermal expansion and excellent thermal shock resistance. This makes cordierite ceramic a predestined material for high-temperature applications with rapidly changing temperature cycles.

Other advantages of cordierite are high electrical insulation, corrosion resistance, high temperature resistance - a material that combines many advantages of a technical ceramic with low manufacturing costs.

The best-known cordierite ceramics are C410, C511, C520 and C530, with C410 and C520 being used for most technical components. C520 has a porous structure in contrast to C410 which is a dense cordierite. If the requirements for the component are very low linear expansion, C410 should be favoured. C530 has high strength and the highest high temperature strength of any cordierite. With the addition of mullite, C530 can be used at temperatures up to 1600°C.

We are specialized in the production of technical components made of cordierite ceramics from a single piece to large series. Almost any shape can be produced by dry pressing, wet pressing or extrusion.

Possible components made from cordierite ceramics include pipes, insulating plates, insulating beads, bushings, discs, washers, rods, plates, spacer rings, bushings, terminals and bases

Your request goes through the following steps after receipt of your drawing:

- Checking the drawing for feasibility

- Advice on the choice of cordierite considering the area of application

- Preparation of the offer

Cordierit ceramic components - prototype manufacture to series production

Through the use of individual manufacturing processes that are adapted to the batch size, we are a strong partner in the construction of prototypes for cordierite ceramics. We manufacture Cordierit ceramic components according to drawings from a quantity of 1 with a short production time. Send us your prototype drawing in PDF format.

Send us your request by email or use the contact form: